Filtration technology by Atec

In the field of water treatment each application is different depending on the type and characteristics of the water, the objective of the treatment, specifics of the installation site and many other factors. Atec offers a wide selection of filtration systems for micro, ultra and nanofiltration.

Each filtration unit can be equipped with filtration membranes from a large number of manufacturers of:

- Polymeric flat sheet membranes

- Polymeric tubular membranes

- Polymeric hollow fibre membranes

- Polymeric spiral wound membranes

- Ceramic flat sheet membranes

- Ceramic tubular membranes

Atec Basic Minitube Filter

The Basic Minitube filter ist the smallest and most economic filtration system by Atec. It is a fully equipped cross flow filtration unit, e.g. ideal for small volume process baths. Thanks to the very space saving design, the filtration unit fits into any existing production facility.

- Very small footprint (Euro pallet)

- Low investment

- Easy installation and start-up

- Easy maintenance

Atec Midtube Filter

The Miditube filter is a compact filtration unit for medium capacities. It combines a large membrane surface area with the typical strengths of the Atec cross flow filtration principle.

The Miditube filter also can be provided in a simplified version for modular applications. By that, several units can be installed in parallel or in series for applications which require high filtration capacities.

- Ideal for medium and large capacities

- Filtration of heavily polluted media

- Low energy consumption and low temperature increase of the water

- High cross flow velocity allows to reach high solids concentration in the concentrate (high permeate recovery rate)

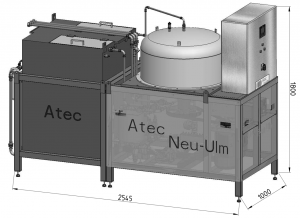

Atec Cartridge Filter / Discfilter

The Cartridge Filter is a well proven solution for industrial process and waste water treatment for many years now. Atec developed the advanced Discfilter based on the Cartridge Filter. The Discfilter can be equipped both with polymeric flat sheed membranes and with ceramic flat sheet membranes. Even with difficult raw water with very high solids content, the Atec Discfilter shows excelent results.

- Very high cross flow velocity

- No clogging of the membrane surface

- High concentrations reachable = high permeate recovery rate

- Low temperature increase of the water

- Large membrane surface area and very space-saving

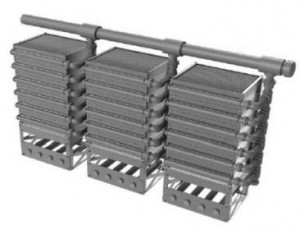

Submerged ceramic ultrafiltration membranes

The modules consist of a large number of ceramic flat sheet membranes and are installed inside a tank under the water level. By means of a low negative pressure, the permeate is extracted from the tank while suspended solids, turbidity and bacteria are retained on the membrane surface. Submerged ceramic membranes are ideal for applications in drinking water filtration and membrane bioreactors (MBR).

- Water without turbidity and bacteria

- Low investment costs per m² of membrane surface area

- Higher recovery rate than sand filters

- Treatment of sand filter backwash water in order to obtain drinking water quality permeate

Containerized filtration systems

All filltration systems for water treatment can be installed inside a 20ft or 40ft seafreight container. The plants are fully or semi-automated and are duely tested in our factory prior to delivery. A large number of optional components (pumps, dosing equipment,…) can be integrated in the containerized system.

- Quick and easy start up on siteSchnelle Inbetriebnahme am Installationsort

- Customer only has to provide concrete slab, electricity, raw water and waste water connections

- Completely integrated optional components (e.g. activated carbon filter, precipitant dosing)

We design and produce your water treatment plant in our facilities in Neu-Ulm, Germany. For the installation, commissioning, repair and after sales business we have our own experienced team. Therefore you can be sure that each Atec water treatment product stands for high German quality.