Water treatment technology

Complete solutions: Design, manufacturing and service

Our business division Atec Environmental Engineering specialized in solutions for the treatment of different kinds of water.

Atec is a full service provider and offers:

- Feasibility studies

- Design

- Manufacturing

- Installation and commissioning

- Training for operating staff

- Repair, maintenance and after sales service

Atec Environmental Engineering provides all services that are necessary from the analysis of the problem to the implementation of the solution. And even beyond that point. Learn about our references.

Atec filtration systems

Since the foundation of Atec the focus of the environmental engineering department is on filtration technology. In general, these filtration systems are the core component of any water treatment system by Atec. There are other complementary technologies which

Membrane filtration is our core competency

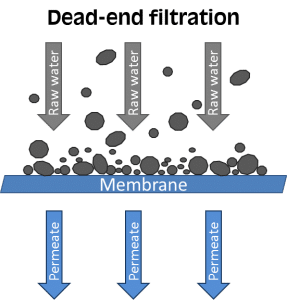

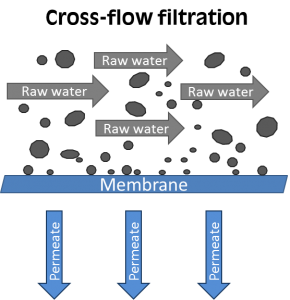

In membrane filtration processes, we distinguish between “dead end” and “cross flow” filtration. Both filtration principles have their specific advantages and disadvantages and special fields of application accordingly. In general, Atec applies cross flow filtration with high tangential flow velocity in industrial applications. This allows to reach a high flux even with difficult media to be filtered.

Dead end filtration

Atec applies dead end filtration sucessfully in the fields of drinking water treatment and membrane bioreactors (MBR). With this filtration principle, there is a dirt layer on the “dirty side” of the membrane which grows constantly. In case of filter presses this layer gets very thick and is called “cake” (“cake filtration”). The dirt layer reduces the effective pore size of the membrane and thereby enhances the filtration process actively. Once the possible or desired thickness of the dirt layer is reached, it is removed by means of backwash or opening of the filter.

Cross flow filtration

Especially for industrial applications Atec generally prefers cross flow filtration. Both for process baths (degreasing, rinsing,…) and in waste water applications, cross flow filtration allows to reach a constantly high permeate flux. Atec filters stand out the competition thanks to their excellent cross flow characteristics. The high tangential flow across the membrane surface limits the formation of a dirt layer and allows to reach very high concentration of solids in the concentrate, which means you reach high recover rates for the permeate.

Microfiltration and ultrafiltration

Using membranes with small pores and applying pressure, suspended solids and particles can be removed from the water. The separation of the different components is defined by the pore size of the membranes used. By applying these filtration processes the following components can be removed:

- Emulsified components: oil and grease

- Suspended solids and particles

- Chemical compounds with high molecular weight

Nanofiltration and reverse osmosis

Like microfiltration or ultrafiltration reverse osmosis and nanofiltration are membrane based filtration methods. With the help of high pressure and special spiral-modules it is possible to remove even extremely small sized particles, larger molecules and ions from the process water. Fields of application are deionization for boiler feed water and certain kinds of production water.

By adding different chemicals (e.g. flocculants or antiscalants) the removal rate can be enhanced and the lifetime increases. This is true for all kinds of membrane filtration mentioned above.

A recent development are ceramic membranes for nanofiltration which Atec already applies successfuly.

According to the task, Atec applies different filtration systems. Learn more about our filtration technology.