Drinking water treatment for disaster relief and development aid

Drinking water supply in disaster areas

In disaster and crisis areas one of the most urgent tasks is the supply of the population and helpers with safe and germ free drinking water. In emergency situations according to the World Health Organization (WHO) every person needs between 5 and 15 litres of drinking water per day for drinking and cooking. In case the emergency situation lasts for several days, weeks or months the water demand rises because water is also needed for personal hygiene. If there is no local drinking water grid or it is damaged, the proximity of the drinking water treatment or distribution points to the affected population is important, because the water is often transported by foot.

That is why it’s important to have a mobile and quickly deployable technology which allows you to set up a reliable drinking water supply. Our drinking water plants are very robust and easy to operate. This makes them ideal for applications in disaster and crisis areas as well as in the field of development aid. The raw water can be extracted from different sources, according to the local circumstances:

- Not drinkable water from public water grid

- Ground water

- Surface water (lake, pond, river)

- Rainwater

Turbid pond water used for drinking water supply during Iran-Iraq earthquake 2017

Mobile drinking water treatment plants

All Atec drinking water treatment plants apply the same technology: ultrafiltration by sumbmerged ceramic membranes. These membranes guarantee safe, turbidity and germ free drinking water. The filtration plants are robust, have a long lifetime and are very efficient, which means the yield/space ratio is very high.

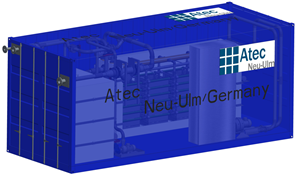

Large scale plants installed inside shipping containers

Fully automatic drinking water treatment plants installed inside standard shipping containers of size 10ft, 20ft or 40ft. The plants contain all components (pumps, tanks, PLC,…) for a full-featured drinking water treatment with capacities from 15 m³/h up to 150 m³/h. All units are preinstalled and tested in the factory, therefore the commissioning on-site just takes a couple of hours.

Depending on the size of the container other treatment steps can be integrated into the plant (e.g. activated carbon filter, elimination of heavy metals, chlorination). In additon, the plants can be equipped with optional components, such as remote control system or pressure booster unit for cleaned drinking water.

Medium size plants

Fully automatic plants with capacities from 1.000 l/h up to 10.000 l/h. The system is mounted on a stainless steel skid and surrounded by a stury stainless steel or plastic casing. This makes these compact plants easy to transport, for example on a trailer or on a pick-up. Also it’s possible to mount the plant on a trailer.

The units can be equipped with additonal components, such as activated carbon filters, chlorination or a remote control module for the PLC.

Small scale “point of use” systems

These very compact units fit on half a standard pallet and provide approx. 200 l/h of turbidity and germ free drinking water. This makes them the ideal solution for drinking water supply at or near the “point of use”, e.g. in case of small remote villages, field kitchens or mobile hospitals. They are easy to operate and after a short training, they can be used and maintained by local staff or the local population.

These systems can also be used as part of development aid projects for the drinking water supply for remote areas or villages without drinking water treament infrastructure.

Large scale plant installed inside a 20ft shipping container

Medium size drinking water treament unit with sturdy plastic casing